Automobile industry is the development trend of energy saving and reduce the burden of environment, in this kind of trend, electric car development soon, the power steering system, the oil pump electric development at the same time, such as car core parts of power transfer function also introduced a new way.

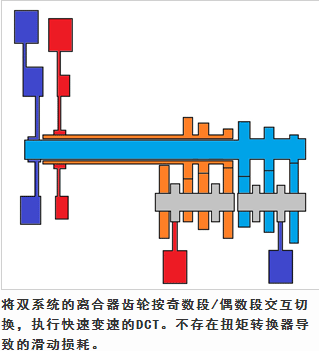

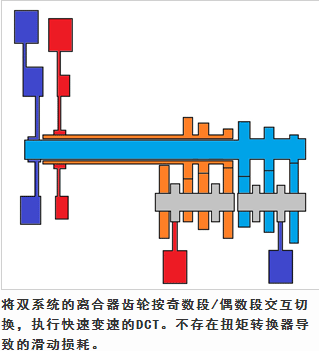

Variable speed device, the DCT (Dual Clutoh Transmission dual-clutch Transmission) caused the attention of people, DCT with odd/even paragraphs, Dual system of clutch and gear, interactive connection double system, in order to perform shift up and down, the time needed for variable speed very short, and as a traditional ats (Automatio Transmission automatic Transmission), no loss, as a result of the torque converter, has the characteristics of the greatly reduced fuel consumption. On the user's consciousness, auto industry trend towards ascension can effect comparing, reduce environmental load, under the trend of not only cars, large passenger cars, trucks, etc used the DCT, even adopted the two rounds of motor vehicle technology, allowing it to spread quickly.

DCT by motor driven hydraulic pump, divided into electromagnetic direction valve is used to switch the electric hydraulic oil pressure type and directly use the electric motor drives the driving point method, the former has an advantage in cost, which is dominant in terms of efficiency and responsiveness. But pure electric mode in the clutch gear installation have driven around two clutch, shift of four motors, the engine room in such a limited space, the motor miniaturization, high output is required. In addition, the clutch is closed, the motor will always maintain electrical activity in the motor itself will be fever, and the engine will heat transfer, temperature rise, easily need cooling measures.

In order to reduce the heating of the motor, the copper wire of the winding group is needed. Moreover, high output is related to coil winding number. Therefore, the DCT motor USES the segmented core to maximize the utilization of space between the cores. In addition, on the basis of considering the thermal design, realization of compact electronic circuit installation method as far as possible, also under a lot of work in selected grease, ensures smooth from low temperature zone to the action of high temperature. Besides, in addition to heat dissipation, it is necessary to ensure the vibration, waterproofing and rust protection in automobile application. More in the future, our company will be on the r&d performance, cost more advantage of the products at the same time, the analysis of the automobile industry is developing electric demand, expand outside support including DCT idle stop the motor and other business.